Client:Sweco

Region:Europe

Industry:Manufacturing

Sweco goes from finance automation to robo-botanists in just two years

150,000

hours saved in 2.5 years

150

processes automated

400

manual tasks mined

Client Overview

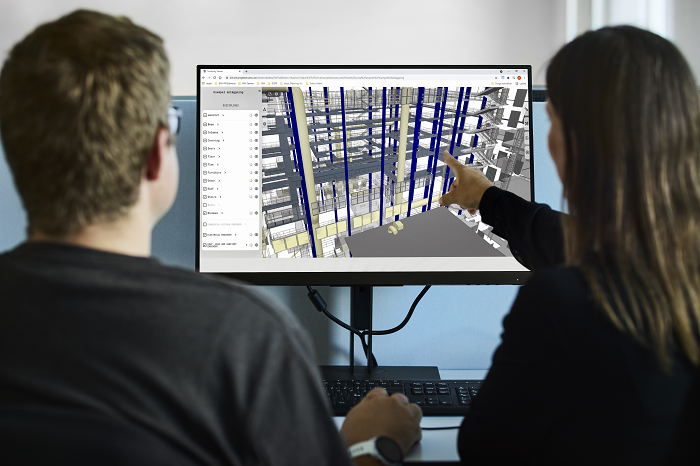

For more than 130 years, Sweco has been transforming society in partnership with its clients. Today, it’s Europe’s leading architecture and engineering consultancy, employing 18,500 people working on projects that span infrastructure, the built environment, and utilities.

When David Hunter, head of artificial intelligence (AI) and automation at Sweco, joined the business in February 2020, he could see the potential for robotic process automation (RPA) was huge but the challenge would be how to implement on a green field “The business was conducting 100,000 projects a year, with opportunity for using enhancing automation technology in nearly all of the projects ,”

As a knowledge business undertaking thousands of projects a year, it was clear automation could quickly get results. “I saw a huge opportunity for RPA to do what it does best: let highly skilled architects and engineers do their work while removing tasks that they do not direct need involvement with,” Hunter continues.

This prompted him to dive in headfirst and bring his vision to life. “I explained to senior management that they shouldn’t do a trial of RPA. As I saw it, there was no point considering if it would work. From day one, it was obvious RPA would make a colossal impact.”

So, Hunter started as he meant to go on. He built a center of excellence (CoE) that'd be big enough to support 100s of automations. By the end of his first month, he’d brought in the UiPath cloud technology he needed, along with specialist developers ready to ramp-up automation at break-neck speed.

“I took care to build a team that brought together development skills with business analytics. We needed developers that could talk to teams, understand their issues and build solutions all in one. There needed to be as little friction as possible.”

This is a crucial point for Hunter. “Our employees are the engine of our company. If they spend too much time going through a laborious process, explaining at length and even trying to build automations themselves, this limits their ability to focus on revenue-generating client work.” His plan was to introduce robots with minimal effort from colleagues.

The first automation

The opening automation was in HR, managing staff onboarding. “It’s still going two-and-a-half years later,” Hunter smiles with satisfaction. “We’re a big business and hire people all the time. HR specialists used to check an inbox for new joiners and manually add their details to the HR system.” Now a robot wakes up every hour to do it automatically.

This begs the question of how the team found this and other processes that were ripe for RPA. “The answer is simple,” Hunter says earnestly. “We do our best to explain the concept of automation to employees using intranet, videos, and other comms. We hold workshops and once people get excited and see the potential, we invite them to suggest ideas.”

At this point, the strong governance process developed by Hunter kicks in. “We have a set of criteria that consider how simple the process will be to automate, its stability and the results we’re likely to see.” Since the program kicked off, there have been over 400 suggestions.

Hunter says the key to building an automation pipeline is speaking to those on the front line of detailed and complex work.

We have taken a strong bottom-up engagement approach combined with our Top-Down strategic vision. Fantastic ideas come from all directions, and we make sure we catch them throughout the organization.

Expanding and gaining trust

This approach has allowed the CoE to introduce robots incredibly quickly. It went from HR into the finance team, to IT, to Legal, and to the Business lines, eventually automating processes on over 50 different production systems. This was a huge win for Hunter.

“When we first spoke of a robot workforce there was some wariness of how it would interact with other systems and even long-term stability.”

Yet within two years, RPA was fully embedded. There are even automations that assesses and monitors other systems. “So, due to a proven track record of incident free performance and efficiency, we have gone from those initial doubts to being a trusted partner working on critical processes and even monitoring ‘traditional IT systems’ and first call for people seeking solutions for problems.” It was quite a U-turn.

Sweco now has 150 automated processes and has saved 150,000 hours for the business. But there’s one automation feature that stands out for Hunter. “About a year-and-a-half ago, we automated the creation of monthly financial reports. It was a big moment when the document landed on our CEO’s desk. She knew robots collated it and was hugely appreciative. It was accurate, timely and saved hours of manual work.”

This automated reporting has been mirrored in other areas. “We have 600 teams that each need a 25-page PowerPoint showing their monthly results. It took a day to collate each one. To put it another way, it would take over 2500 hours of manual work a month. We’ve cut that to a single day for all reports, which is limited by the fact that PowerPoint works quite slowly.”

At this point, Hunter makes an important point.

This is a classic example of a great automation. It took 80 hours to develop the robot. But it performs the equivalent of 30,000 hours a year. The return on investment is staggering in cases such as this.

David Hunter • Head of artificial intelligence (AI) and automation

Making the most of every robot

Impressively, the CoE has achieved all this with just a handful of robots. “Their scalability has been incredible,” he enthuses. “We built the platform and stuffed it with as many tasks as possible.” The developers can now automate about 11 processes a year each, which is a great result.

And the business has welcomed each robot, with each receiving a name. “We have Urban, who works on financial tasks – and is therefore seen as the most important. Then there’s Anna, Bono, Carl, Dora, Ella, Fred – who works in Finland – and Sarah. Sadly, Bono doesn’t work in Ireland,” Hunter quips. “They’re all classed as virtual workers on our HR system.”

It’s a simple thing to do but giving the robots names encourages colleagues to use them. “I often get people asking, ‘can you get Fred to do this for me?’ Or ‘what’s Urban doing today?’ I stop myself from saying, ‘do you realize this is a piece of software?’ I take it in my stride.”

Minimal challenges

When asked if he’s experienced challenges with the introduction of RPA, Hunter references those with concerns about robot stability. But his overwhelming feeling is that automation is seen as positive and warmly received by practitioners.

“It’s, in Sweco’s culture as knowledge company to nurture our people” he says. “However, what we do have are people who might sometimes have felt overworked owing to repetitive tasks that are actually a better fit for a robot, so we give those to our robot work force and instead let our people concentrate on our customers projects.”

With this comment he recalls a story. “There was one person responsible for creating a report to be ready at eight every morning. This meant getting up at six, trying to deal with kids going to school and stressing about getting it right and on time. We automated the task, and it changed their life.”

Planning for the future

Thinking about the future, Hunter says until now, he’s focused on getting basic RPA embedded in the business. But his team is quickly incorporating artificial intelligence (AI) with robots to create intelligent automation (IA). “This is a game changer,” he says.

“If RPA can automate things we already do, IA can automate tasks we’d never be able to, unlocking huge value in the business.” For example, a robot recently read 5.4 million PDFs of old architectural blueprints. Using optical character recognition (OCR) and AI, it identified 4,500 that were reusable. “We’d never have been able to do that before. Imagine reading all those documents. Yet the robot did it in three days.”

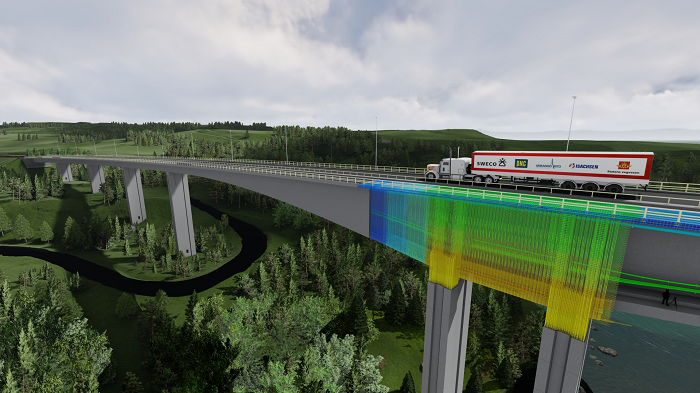

Construction often involves management and the careful protection of the environment for wildlife and plants. We can use robots to create protection plans, and we can even use AI to automatically detect the animals and plants in the area to make sure the plan is accurate to the actual changing nature.

David Hunter • Head of artificial intelligence (AI) and automation

A word from the wise

When asked what advice he’d give to others embarking on their automation journey, Hunter says, “Quickly build an operational model that works well and protects you from challenges. Then trust the process and act quickly.”

By this he means not wasting hours and days prioritizing. “Find an idea, develop it quickly and roll it out. Every moment a process isn’t automated is more time wasted. Our evaluation process takes seven-and-a-half minutes.”

“Also, don’t worry too much about what you can achieve today. Look to tomorrow. The software develops so rapidly that if you focus on the now, you’ll forever be behind the curve,” Hunter confides.

In summary, he says, “There’s no point trialling RPA. It will work. So, get on with it. But make sure it’s developed closely with the business and those who use it. Finally, remember there is a virtue in velocity. Develop, develop, develop.”

It might be daunting to think like this, especially when faced with a green field and no precedence for RPA. But that’s exactly what Sweco’s CoE has done. And it’s been a tremendous success.

Related case studies

Ready for your own case study?

Speak to our team of knowledgeable experts and learn how you can benefit from agentic automation.